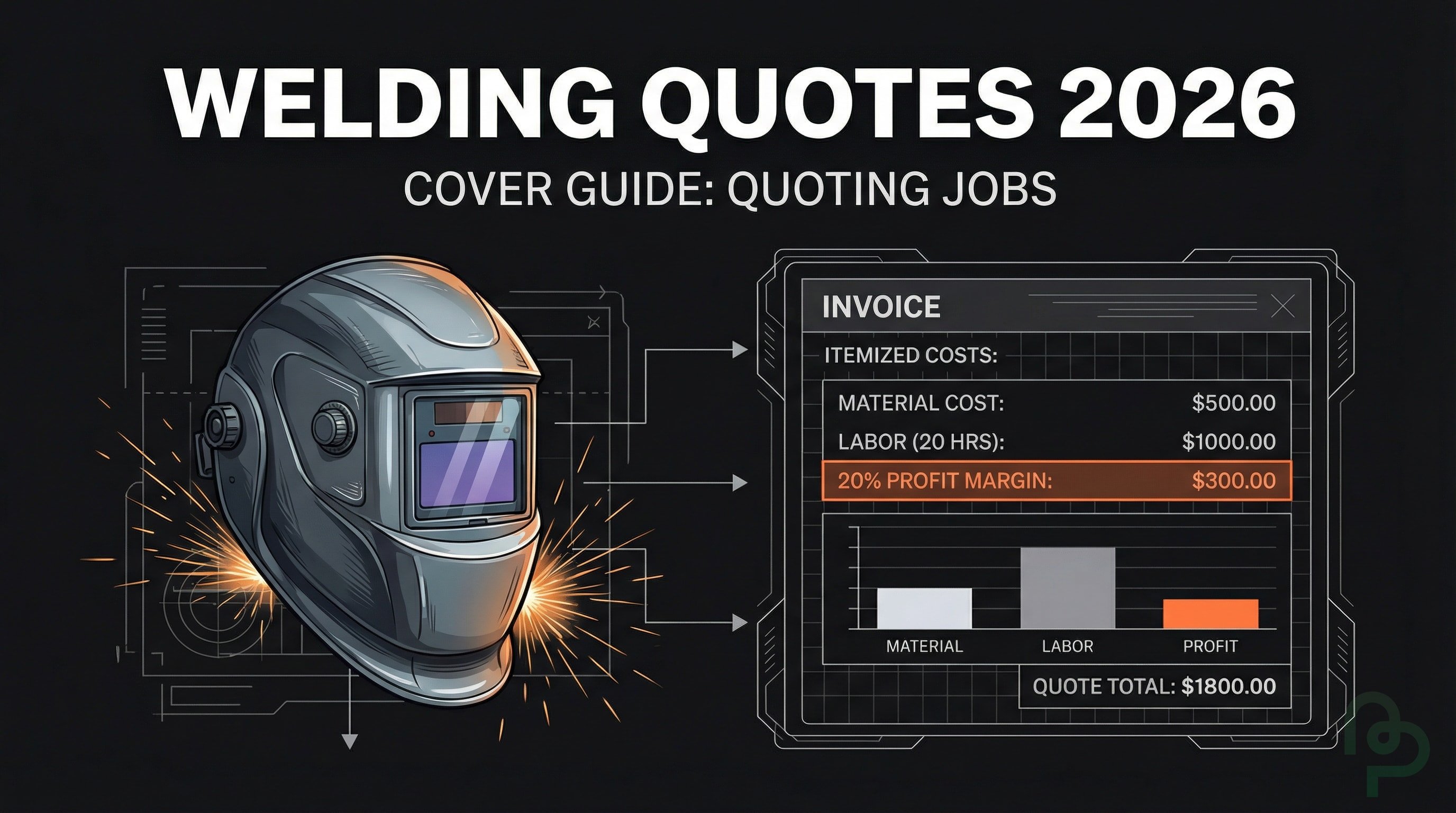

How to Quote Welding Jobs: A Guide to Profitable Pricing

Estimating errors in construction and trade projects typically range between 5% and 10% (Procore, 2024). For a welding shop, these minor miscalculations represent the difference between a thriving business and one struggling to cover the cost of gas and consumables. This guide provides the framework for calculating shop rates, managing material volatility, and delivering professional quotes that win high-value contracts.

The Financial Gravity of Inaccurate Welding Quotes

Underquoting a project doesn't just reduce your take-home pay; it actively drains your business's operating capital. When a welder quotes $5,000 for a structural steel repair but fails to account for a 6.77% spike in industrial gas costs, that narrow profit margin vanishes instantly. You aren't just working for free; you're paying for the privilege of working on the client's project.

Precision in quoting is particularly vital because of the high "Cost of Goods Sold" (COGS) in metal fabrication. Welding involves significant invisible costs, from the depreciation of an $8,000 TIG welder to the rising price of shielding gases like Argon and CO2. If you don't factor in a 10% waste buffer for materials, you'll find that your "estimated" profit is swallowed by the scrap bin.

Furthermore, the complexity of the welding process—TIG vs. MIG, overhead vs. flat, or stainless vs. mild steel—requires different labor intensities. A quote that treats all "welding time" as equal is a quote designed to lose money on difficult jobs. You must differentiate your rates based on the skill level and equipment required for specific weld types.

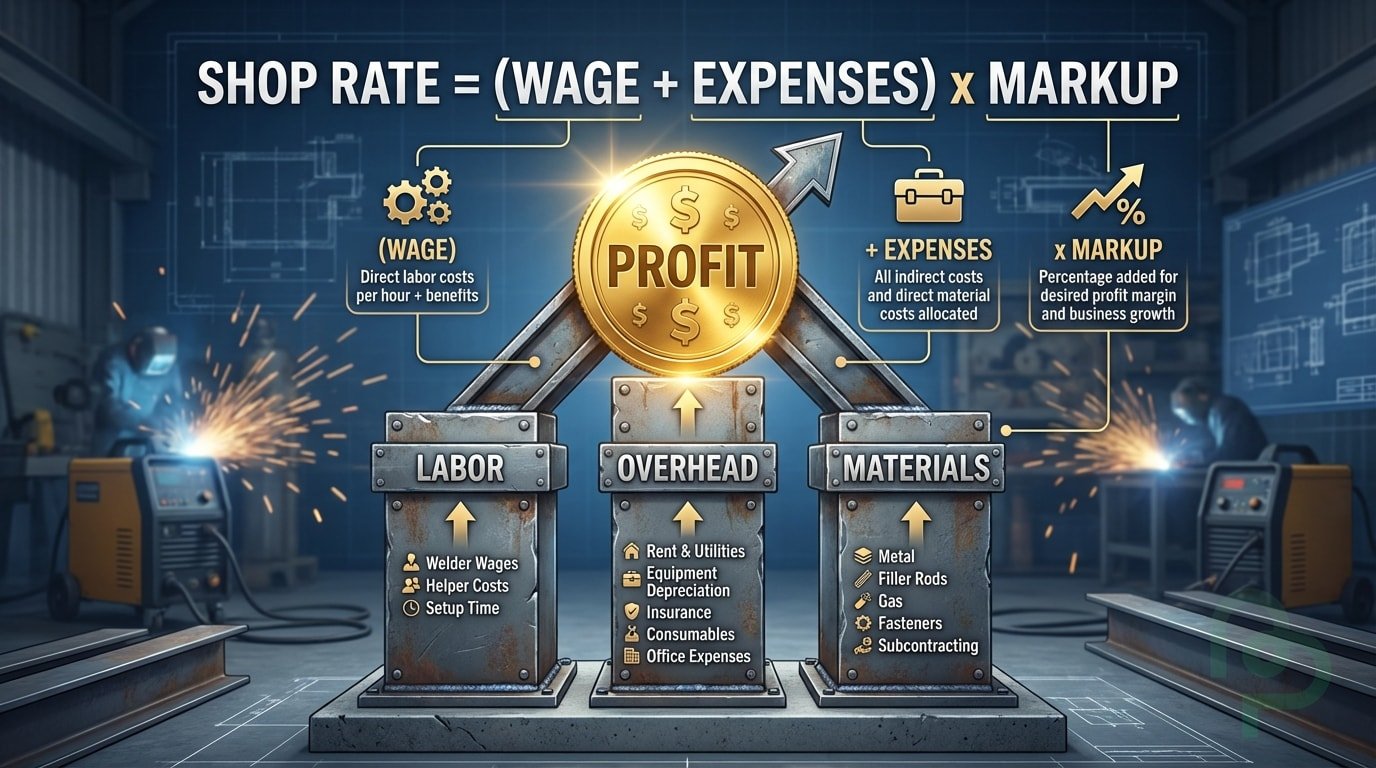

Mastering the Three Pillars of Welding Pricing

To build a quote that protects your bottom line, you must treat your pricing as a tripod consisting of labor, materials, and overhead. If one leg is weak, the entire financial structure of the job collapses. Most independent welders make the mistake of only charging for their time, ignoring the fact that their shop's rent and electricity continue to cost money every hour the hood is down.

Labor rates should reflect both local market demand and your specific expertise. While the average hourly wage for a welder in the U.S. is approximately $23.53 (Bureau of Labor Statistics, 2024), your "shop rate" must be significantly higher to account for taxes, insurance, and profit. Successful shops often set their billable rate between $60 and $120 per hour depending on the specialty.

Materials and consumables must be marked up to cover the time spent sourcing and transporting them. It isn't enough to pass through the cost of steel from the local supplier. You should apply a 15–30% markup on all physical goods. This covers the "handling cost" and provides a buffer against the rapid price fluctuations common in the metal industry.

High-Impact Quoting Strategy: Step-by-Step

Determine the Project Scope and Method

Identify if the job requires Stick (SMAW), MIG (GMAW), or TIG (GTAW). TIG welding generally commands a 25% premium due to the precision required and the slower travel speeds. Determine if the work is shop-based or mobile, as mobile rigs require an additional "call-out" fee to cover fuel and vehicle maintenance.

Calculate Total Direct Costs

List every foot of filler wire, every cubic foot of gas, and every grinding wheel needed. If you are quoting a $2,500 custom gate, don't forget the hinges and latch hardware. Add a 10% contingency to your material totals to account for mistakes or metal price changes between the quote and the purchase date.

Apply the Shop Rate Formula

Use the formula: (Labor Rate + Hourly Overhead) x Profit Markup. For example, if your labor is $40, overhead is $20, and you want a 20% profit margin, your hourly shop rate is $72. Multiply this by the estimated hours to find the base labor cost for the quote.

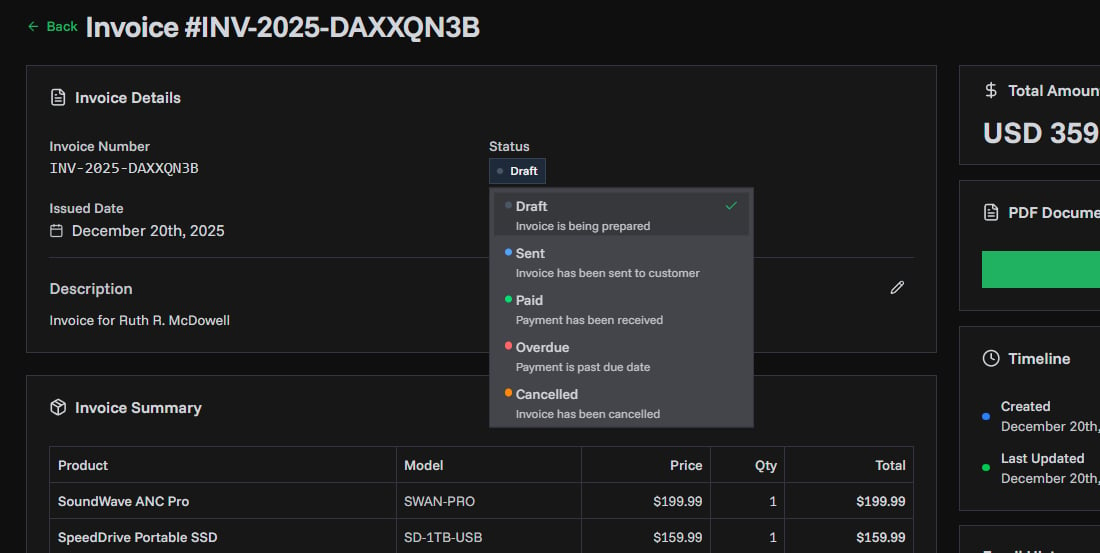

Standardize with Professional Tools

Moving away from paper notes is essential for growth. Tools like PineBill allow you to save your standard rates for different types of welding (e.g., $95/hr for TIG, $75/hr for MIG) so you can generate professional PDFs in seconds. The faster you deliver the quote, the higher your conversion rate.

The Cost of Underquoting: A Data Comparison

Choosing the wrong pricing model can cost a solo welder over $10,000 in lost revenue annually. Below is a comparison of how different project types should be structured to ensure all costs are captured.

| Project Type | Pricing Model | Avg. Hourly Rate | Key Financial Factor |

|---|---|---|---|

| Custom Fabrication | Flat Rate | $85 - $150 | Must include 15% contingency |

| Emergency Repairs | Hourly | $120+ | Min. 2-hour call-out fee |

| Manufacturing Sub-Contract | Per Unit | $60 - $85 | Volume discounts on gas |

| Structural/Code Work | Hourly | $100 - $200 | Includes insurance/cert costs |

Source: Invoice Fly, 2025

Key Takeaways

- Factor in Gas Spikes—Industrial gas costs rose nearly 7% in a single year; always use current pricing.

- Use a 10% Buffer—Always add a waste factor to material takeoffs to protect your margins.

- Differentiate by Skill—Charge a higher premium for TIG and certified code work compared to basic MIG repairs.

- Separate Mobile Fees—Portable welding should include a minimum call-out fee of $100+ to cover travel and higher liability.

- Automate the Process—Using software like PineBill ensures your branding is professional and your math is accurate every time.